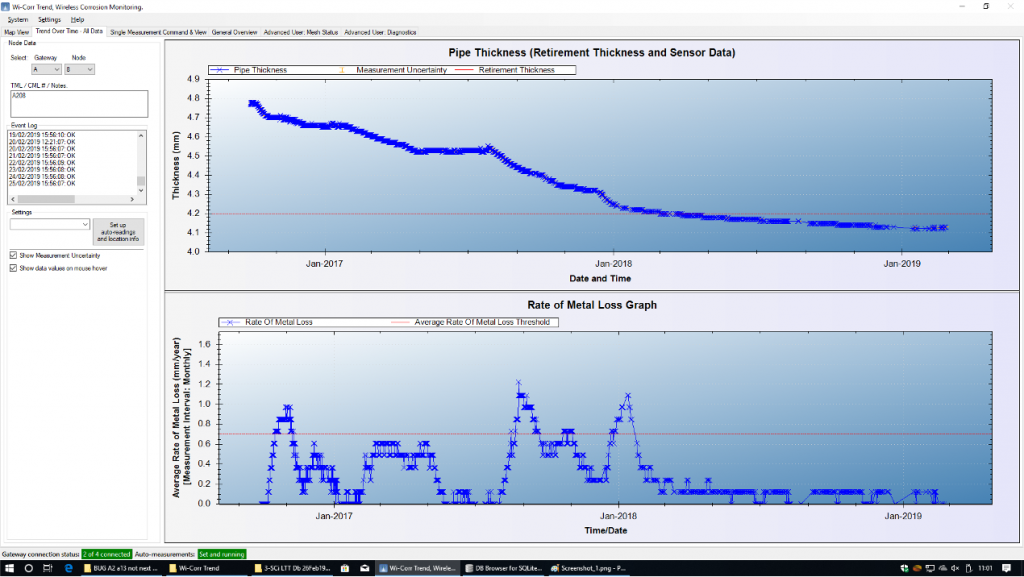

Wi-Corr® UT is a revolutionary wireless monitoring system. Through a self- organising network of permanently installed, wireless enabled sensors, accurate pipe wall thickness and temperature can be obtained cost- effectively, enabling corrosion and erosion to be precisely monitored. This information allows a proactive approach in planning of turnarounds and preventative action

Corrosion and erosion-related failures of processing facilities are a major source of risk to upstream and downstream assets. Manual ultrasonic inspection of pipes gives poor reproducibility. Escalating costs are incurred by deploying inspection teams to facilities, obtaining work permits, preparing scaffolding, or in abseiling to access difficult locations.

In response to these challenges, Wi-Corr® UT has been developed to revolutionise the way asset integrity is assessed.

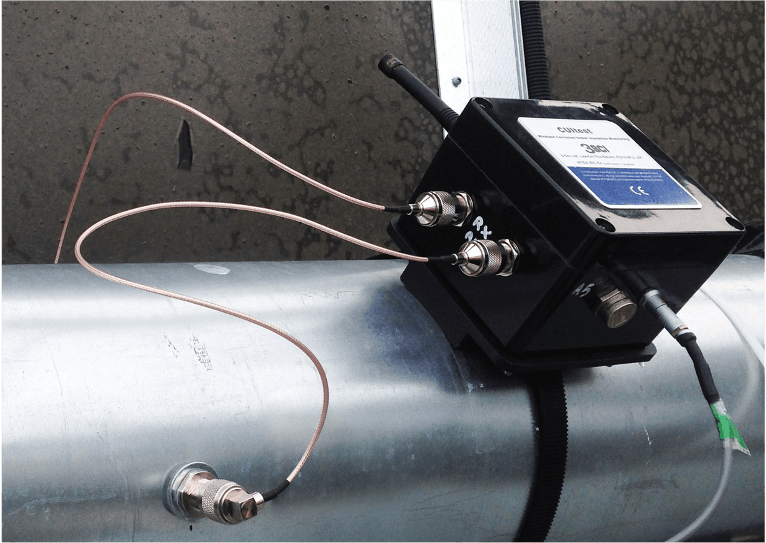

Certified for explosive atmospheres (IECEx and ATEX Zone 1).

Reduces operational risk with non-intrusive sensors.

Easy, quick, permanent or temporary installation on live plant. No hot work permits necessary.

Earliest detection of metal loss with field- proven industry-leading 0.01mm resolution.

Low profile sensors, can be installed under insulation.

+5 year battery life, live plant replacement.

Automatic reporting and historical trending with easy-to-use software.

Separate wireless and sensing modules provide flexibility in locating transmitter to maximise RF range and minimise repeaters. .

Scalable. Large or small scale deployments.

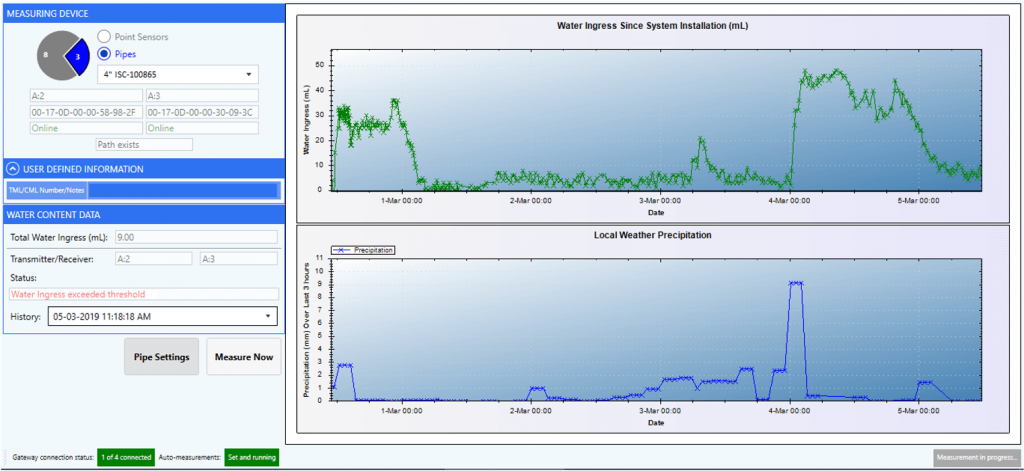

Wi-Corr® CUI is a revolutionary new monitoring system. Through a self-organizing network of permanently installed, wireless-enabled sensors, accurate measurements of moisture content of the thermal insulation over small or large distances can be obtained cost-effectively, so that the conditions that cause Corrosion Under Insulation (CUI) can be precisely monitored.

This information allows concentrations and movements of moisture in insulation to be tracked over great distances, enabling a proactive approach in planning of turnarounds and timely preventative action

The sensor data can remotely detect and predict corrosion development using advanced models and analytics. This can be incorporated into the existing asset management system of the asset owner. Data is used to greatly enhance an existing Risk Based Inspection (RBI) programme, and enabling the move to predictive corrosion management

Earliest possible detection of potential CUI problems with overall plant dahsboard.

Reduces operational risk with dispersed sensors.

Easy, quick, permanent or temporary installation on live plant. Low profile, wireless sensors, can be installed under insulation. Large or small sensor number deployments.

+5 year battery life, live plant replacement.

Automatic reporting and historical trending with easy-to-use software.

Measurements on demand 24/7.

Separate wireless and sensing modules provide flexibility in locating transmitter to maximise RF range and minimise repeaters.

Scalable. Large or small scale deployments.

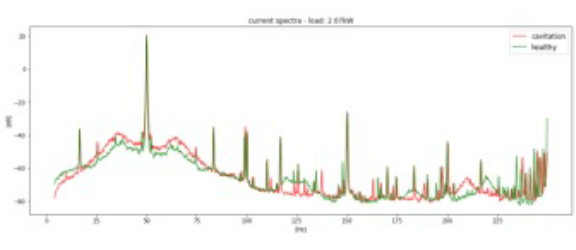

Accurate, intelligent, and powerful machinery analyses and protection based on 30 years of experience.

Global customer support and sales network.

Proven reliable with installations worldwide on all types of critical rotating equipment.

24/7 customer support capability.

Made in Germany.

Online condition monitoring.

SIL 3 machine protection.

Automated diagnostics.

Failure pattern database for clear text messages.

Ring buffer.