Tribosonics is a technology company specialising in ultrasonic sensing solutions for the Industrial and Energy sectors. By addressing challenges in friction, wear, and lubrication, Tribosonics helps industries save energy, reduce costs, and cut carbon emissions on a global scale.

With a multi-disciplinary team of engineers, scientists, and industry experts, Tribosonics transforms advanced research into practical products that deliver high-value smart data. Its solutions enable real-time asset monitoring, process optimisation, and long-term commercial value for business and industry

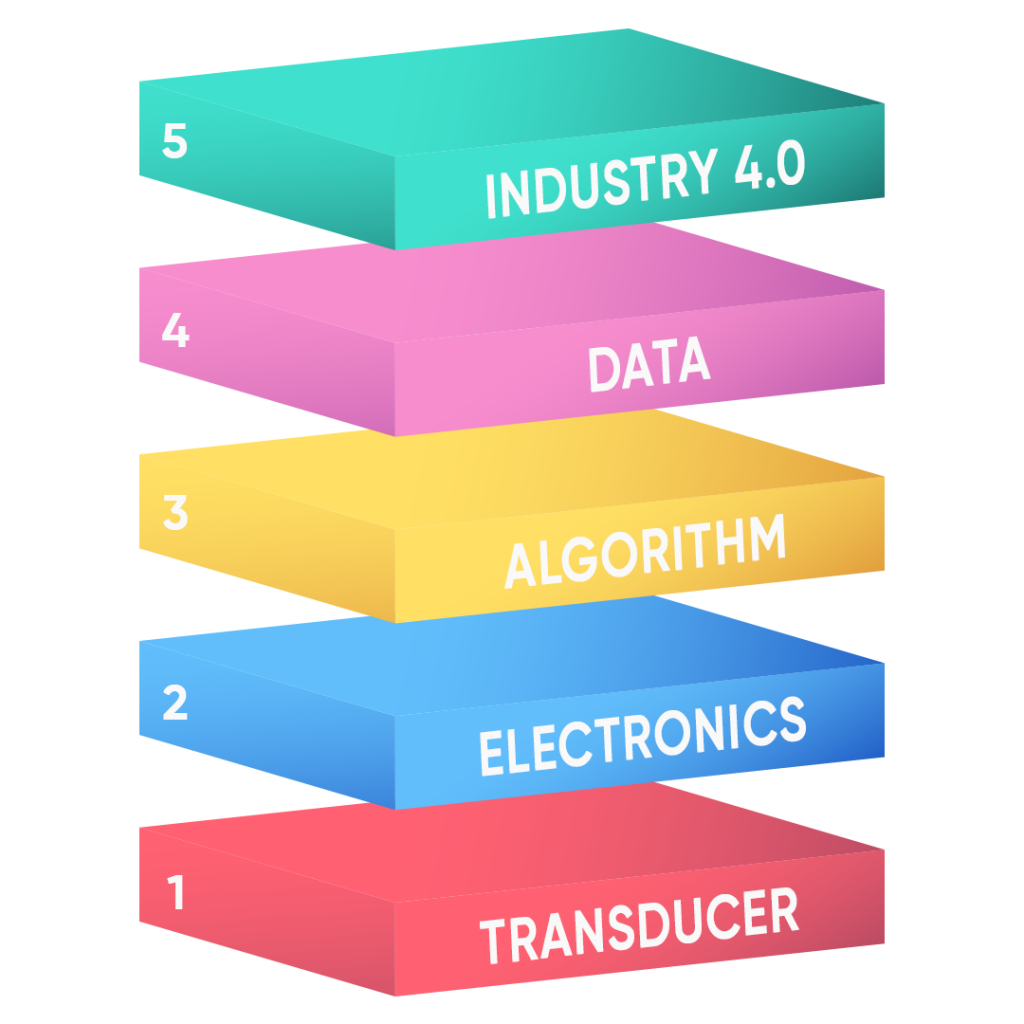

Tribosonics combines advanced technologies in innovative ways to deliver complete end-to-end sensing solutions for industrial and energy applications. The Tribosonics Tech Stack represents a fully integrated suite of technologies designed to meet specific customer requirements with precision and flexibility.

Converts electrical energy to ultrasonic energy and vice versa, enabling component-level integration within industrial systems.

Transforms electrical signals into digital form and supports seamless system-level integration.

Converts digital signals into measurable data through multiple algorithms tailored for diverse performance metrics.

Enhances system and component understanding for OEMs and end-users, driving insights through new data streams and analytics.

Powers digital transformation by enabling new business models and offering systems or equipment outcomes as a service.

Through this layered approach, Tribosonics transforms raw signals into meaningful insights, empowering industries to improve efficiency, reliability, and sustainability across operations.

Tribosonics builds long-term strategic partnerships with clients to deliver measurable value through the application of innovative sensing technologies.

The company’s expertise spans four core service areas:

Tribosonics leverages an extensive measurement technology portfolio focused on six key categories:

Industry-leading ultrasonic reflection technology to measure ultra-thin lubrication layers, essential for reducing wear and improving energy efficiency.

Advanced inspection techniques that ensure safety and reliability without disrupting operations.

Monitoring internal stress levels to prevent fatigue and structural failure.

Accurately tracking material degradation for better maintenance planning.

Measuring surface interactions to improve mechanical performance and product durability.

Analysing fluid characteristics to ensure process stability and quality control.