Machine Learning and Artificial Intelligence

(Wireless Vibration Sensor)

FEATURES

10 kHz FMax

Excellent vibration coverage of both high and low speed machines.

High bandwidth provides precision measurement and good early warning capability for a wide range of fault types.

64G Peak Vibration

Autoscaling ensures excellent accuracy even on low energy machines.

IP69K Ingress Protection

ATEX and IECEx available on request.

5+ Year Replaceable Battery

Adjustable configuration allows for a further increase of battery performance.

Sampling Frequency

Kappa X captures a time waveform at a sample frequency of 25.6kHz. This resolves to a 10kHz FMAX (maximum frequency) for analysis at 6400 LOR (Lines of Resolution). This is ideal for vibration analysis of industrial machinery, covering any applications running from nominal to very high speeds, such as gearboxes. It is possible to envelope the signal using Sensoteq’s Analytix platform to provide an unparalleled level of diagnostic capability in a wireless sensor.

Smart Wake

By sensing the vibration generated from your machinery, the Kappa sensor can enter an ultra-low power mode to save battery life. As the machine turns on, the sensor will start to capture vibration data again with the first waveform being taken at a key moment during the duty cycle of your machinery.

Auto-Ranging

With a minimum range of +/-8G the Kappa sensor will detect even the smallest faults. Other applications are designed to induce vibration as part of the process, causing a very high energy signal. The Kappa sensor will automatically scale up to +/-64G to cope with this increased vibration, ensuring every high energy peak is captured. Our robust Auto-Ranging technology will ensure every waveform is captured at the right range.

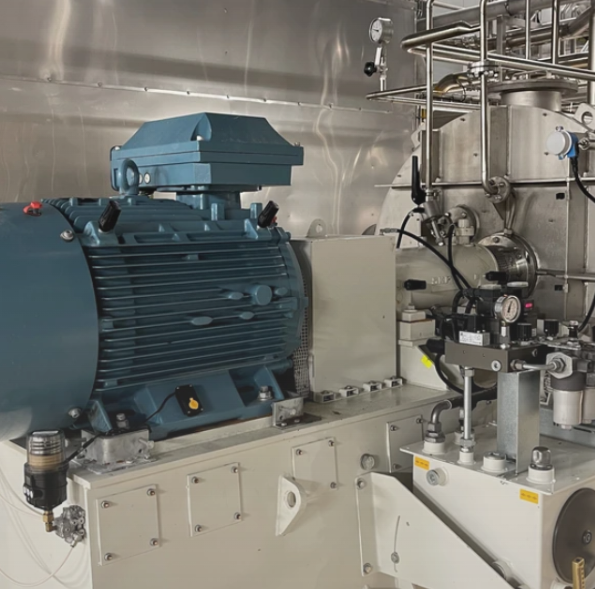

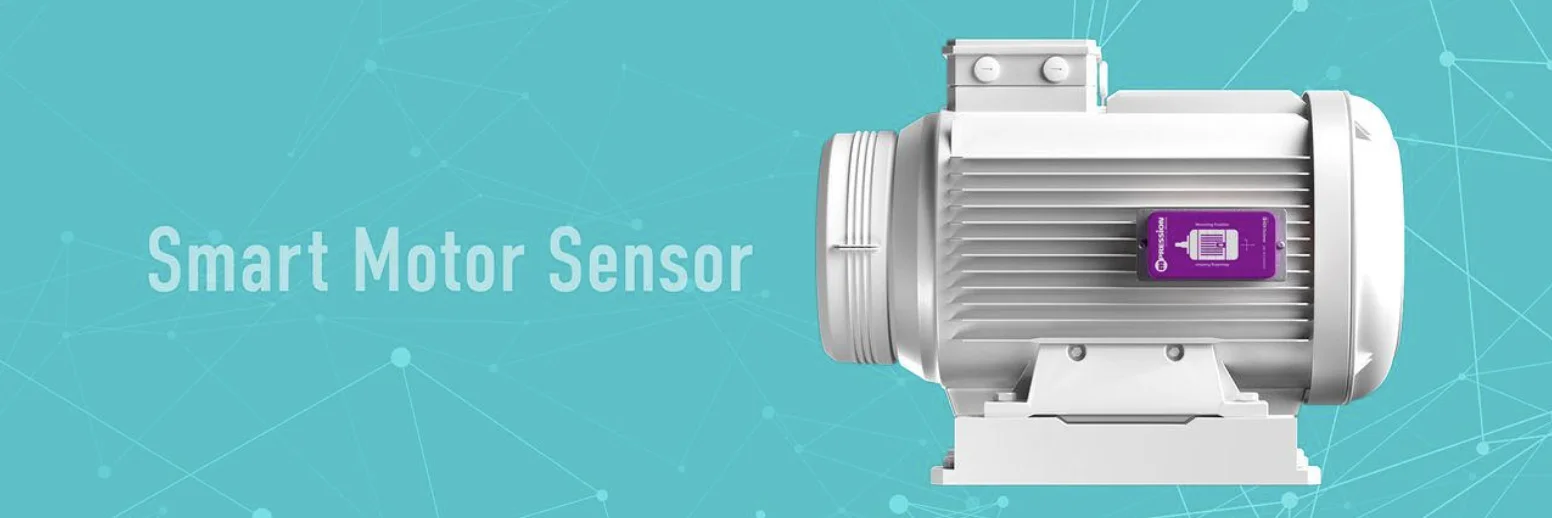

Prescriptive Maintenance Smart Motor Sensor

ADI OtoSense Smart Motor Sensor (SMS) monitors the condition of your electric motors by combining best-in-class sensing technologies with leading-edge data analysis. ADI OtoSense SMS detects anomalies and defects in equipment, enabling you to forecast maintenance cycles and avoid unplanned downtime.

Agnostic of motor type, ADI OtoSense SMS covers the most critical diagnostics, translating data into actionable insights. The Smart Motor Sensor allows for 24/7 condition-based monitoring of all your low voltage electric motors. It presents information in a clear way, telling you both what the problem is and how to fix it.

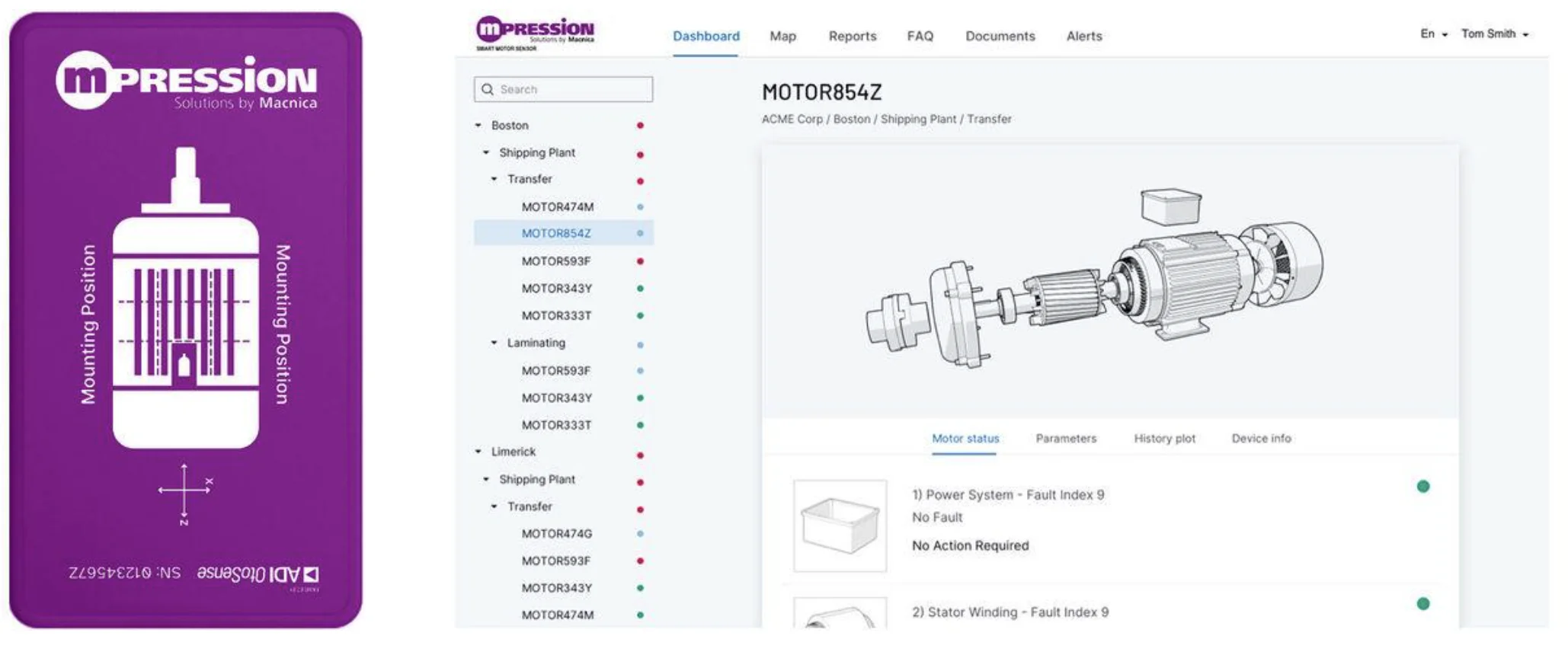

SYSTEM DASHBOARD

Three features of smart motor sensors

Easy installation!

Battery powered (4 AA batteries) Wi-Fi compatible, no wiring required

No expertise required!

Start learning and diagnosis automatically Immediate alarm notification for abnormalities

Nine abnormal modes!

Equipped with 9 motor-specific failure modes Notification of specific points and countermeasures