Asset Registry, Monitory and Risk Assessment

(Wireless Corrosion CUI Monitoring (Wi-Corr® CUI))

Wireless Online CUI Monitoring (Wi-Corr® CUI)

Wi-Corr® CUI use innovative solutions to manage CUI potential threat

CUI (Corrosion Under Insulation) is any type of corrosion that occurs due to water trapped under the insulation or fireproofing of pipes, pressure vessels or any other structure. CUI is a major industrial challenge with many industries dedicating 10% of their total annual maintenance budgets to repairing damage caused by CUI. At present, it is managed in many ways, ranging from full removal of insulation to the use of sophisticated and costly instrumentation.

We believe that insulated pipework should never fail due to external corrosion and that monitoring for CUI conditions to prevent failure should be affordable and effective.

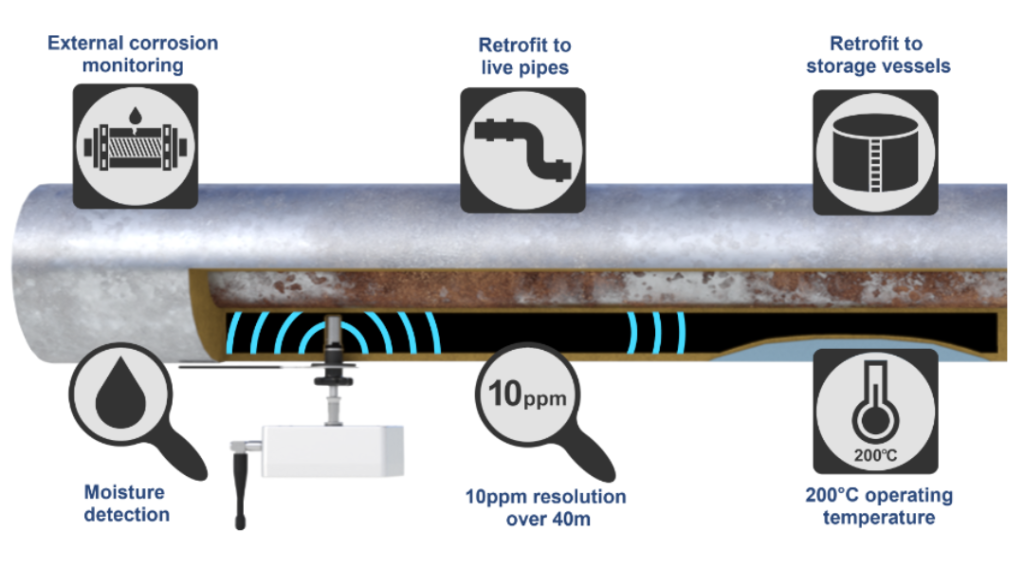

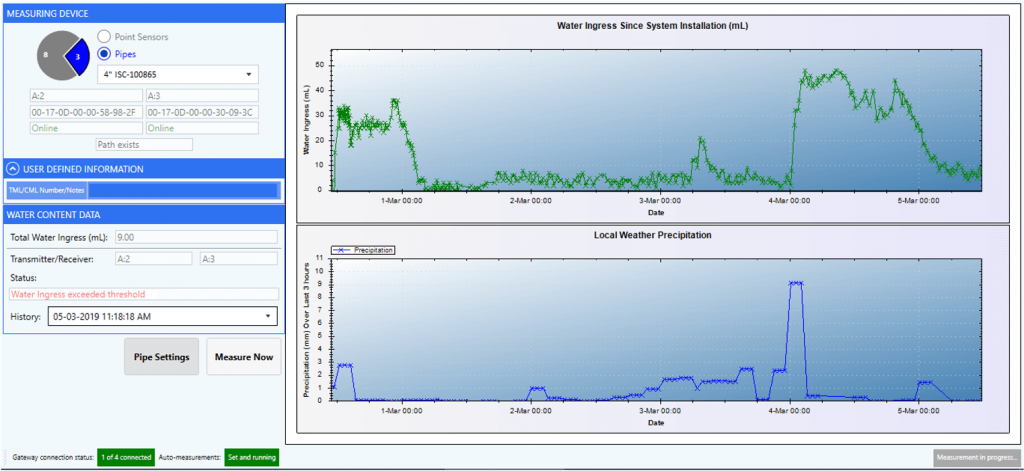

Wi-Corr® CUI is the first wireless, retrofittable system capable of monitoring real-time for the conditions that cause corrosion under insulation. Wi-Corr® CUI integrates with the Trend Software and Data Platform and our proprietary algorithms to analyse the real-time data streamed from our easy-fit CUI sensors. Together they present clear, actionable information for a powerful new approach to addressing the huge cost of corrosion due to CUI.

Earliest possible detection

‘Treat the cause – not the symptoms’

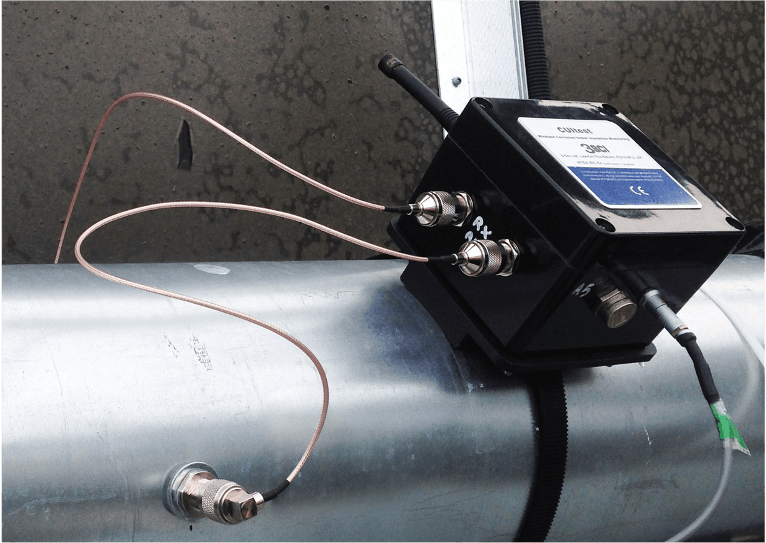

The Wi-Corr® CUI system is underpinned by patent-pending technology that turns an entire structure including its insulation into a sensing, coaxial cable-like structure. Radio waves injected into the insulation travel along the pipe up to 40 metres to detect corrosive environments. This enables a new systematic and data-driven approach to managing the corrosion as well as offering greater sensitivity to moisture build-up than established technologies.

Wi-Corr® CUI enables dramatic reductions in engineering costs through the earliest possible detection of the causes of CUI and through prompt identification of failing thermal insulation and associated energy inefficiencies.

Easy and non-intrusive installation

The simple installation process offers rapid and flexible deployment of sensors with minimal disruption. Sensors are easily retrofitted within minutes to live pipes and vessels without the removal of cladding or insulation, requiring only a small hole in the cladding to insert the CUI sensor. IP66 leak-proof seals on all CUI hardware ensure installed equipment doesn’t produce a water ingress risk.

Once installed, sensors are powered autonomously with a 6+ year battery life under normal conditions. Batteries can be replaced easily at any time on a live plant. Devices can also be repositioned to a new location in minutes.

No permits required for operation and no hot-work permit is required for installation due to the Wi-Corr® range of pipe-safe installation tools. An excellent alternative to any application that might otherwise involve extensive permitting, engineering, cabling, and installation costs.

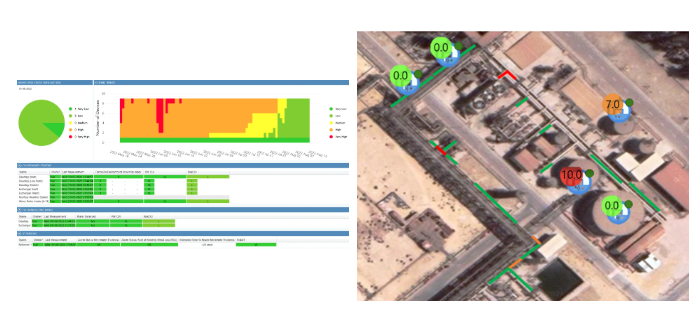

Descriptive and actionable information

The integrated RBI (Risk Based Inspection) solution within Wi-Corr® Trend Software and Data Platform delivers accurate, descriptive diagnostics and visualisations. With actionable information and a clear interface, it can be used to help prioritise maintenance activity and assess maintenance performance, enabling better use of resources and reducing time in the field.

Versatile solution for challenging environments

Compatible with widely used steel or aluminium cladding on all insulated structures inclusive of pipe bends, tees, steam tracers, tanks and vessels. Unlike other technologies, the Wi-Corr® CUI system is not just limited to non-ferromagnetic aluminium claddings and can be applied to the vast majority of clad structures in industry. Compatible with process temperatures up to 200ºC, giving full coverage of CUI threat temperatures.

Monitoring data is delivered over WirelessHART, the most secure, reliable, self-organising wireless network available. The industry recognised wireless technology is proven in cluttered industrial environments. The data is compatible with your existing DCS. Cellular and cloud networking can also be provided as an option if preferred.

Benefits Wi-Corr® CUI

A practical and efficient way of using field data to enhance the ‘Plan, Do, Check, Act’ (PDCA) process of mitigating unacceptable CUI risk in the most effective way, thereby improving plant safety and LOPC.

Rapid ROI is assisted by embedded descriptive, diagnostic and predictive analytics which deliver fast, actionable information.

- Creates a dynamic asset data-driven RBI – asset categorization and prioritization can adapt in response to present field conditions.

- Wi-Corr® Trend RBI outputs can be easily integrated within existing operation and maintenance programs and procedures with minimal disruption to existing processes.

- RBI process based on best industrial working practices.

Sensors are easily retrofitted within minutes to live pipes and vessels without the removal of cladding or insulation

- Requires a small hole in the cladding to insert the CUI sensor.

- No permitting required for operation and no hot-work permit required for installation due to the Wi-Corr® range of pipe-safe installation tools. An excellent alternative to any application that might otherwise involve extensive permitting, engineering, cabling, or installation costs.

- No interruption to operation processes.

- Repositionable solutions – sensing systems can be moved to a new location in minutes

Earliest possible detection of CUI. Greater sensitivity to moisture build-up than established technologies, typically 10ppm over a 40m pipe section.

Unlike other technologies, the Wi-Corr® CUI system is not just limited to non-ferromagnetic aluminium claddings and can be applied to the vast majority of clad structures in industry.

Delivers CUI monitoring data over the most secure, reliable, self-organising wireless network available, compatible with your existing WirelessHART network. DCS ready to integrate.

- Proven in cluttered industrial environments.

- Cellular and cloud networking can be provided if desired by the user.

Compatible with process temperatures up to 200ºC, providing full coverage of CUI threat temperatures.

IP66 leak-proof seals on all CUI hardware ensures installed equipment doesn’t produce water ingress risk.

Compatible with monitoring all insulated structures inclusive of pipe bends, tees, steam tracers, tanks and vessels.

Wi-Corr® CUI units are autonomously powered and designed for 6+ year battery life under normal operating conditions. Batteries can be replaced easily at any time on a live plant.

Data reporting system up and running from first installation using intuitive software. Expandable system. When new sensors are added to an existing Wi-Corr® installation they are automatically recognised

Can be used for :

- Short-term monitoring to deduce the status of regions of concern.

- Mid-term monitoring to assess cladding performance during variations in process and climatic conditions.

- Long-term monitoring for assurance of asset condition.

CUI Sensor Solutions

Choose from our selection of sensors for your needs, with Wi-Corr® CUI Quanta, optimised for pipes, and Wi-Corr® CUI Proximity, suitable for both pipes and storage vessels.

Wi-Corr® CUI Quanta

- Guided wave technology used to detect and quantify water.

- Precise, long range moisture detection.

- Optimised for insulated pipes.

- Compatible with rockwool / mineral fibre insulation. Other insulations on request.

- Quanta units can monitor up to 40 metres of pipework.

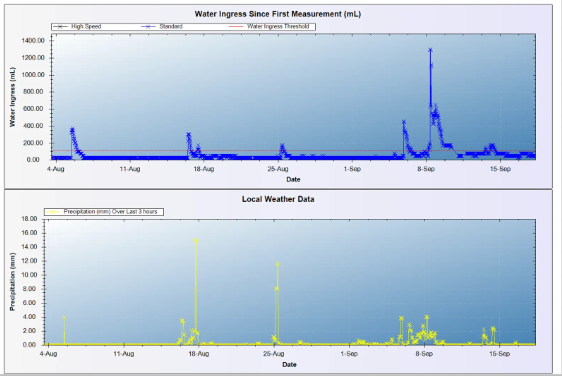

The Quanta technology produces a definitive detection and quantification of moisture between two Quanta sensors separated by up to 40 metres. Due to the unique sensing technology of the Quanta system, the ability to detect moisture is maintained across the entire length of pipe.

Wi-Corr® CUI Proximity

- Humidity sensors and software analytics used to deduce the presence of moisture.

- Close proximity moisture detection.

- Compatible with vessels and pipes.

- Compatible with all insulation types.

- Detects both humidity and direct moisture immersion.

CUI Proximity sensors perform well in scenarios where the moisture is located relatively close to the humidity sensor, outperforming simpler sensing methods such as ‘water bucket sensors’. With our Wi-Corr® Trend analytics, high confidence moisture readings are possible in an enhanced distance from the sensor, proven in real-world trials.

Certainty of the moisture concentration is limited by proximity. When the presence of moisture is possible over a large area, 3-Sci recommends Proximity sensors are placed at least every 5 metres.

Asset Integrity and Monitoring

Wireless Corrosion UT Monitoring

(Wi-Corr® UT)

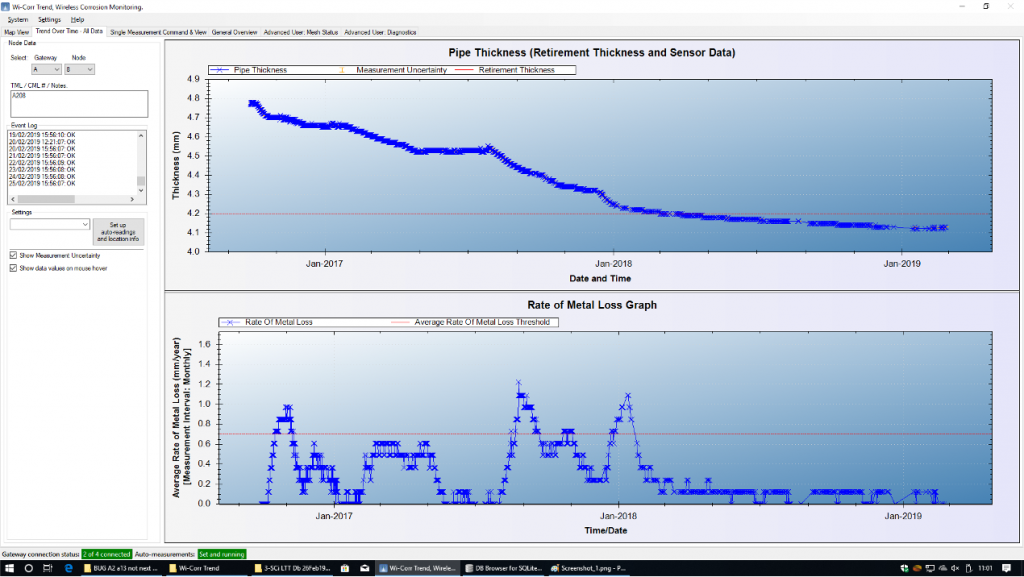

Wi-Corr® UT is the market leader for the highest sensitivity measurement in the industry

Wi-Corr® UT is a revolutionary wireless monitoring system. Through a self- organising network of permanently installed, wireless enabled sensors, accurate pipe wall thickness and temperature can be obtained cost- effectively, enabling corrosion and erosion to be precisely monitored. This information allows a proactive approach in planning of turnarounds and preventative action

Corrosion and erosion-related failures of processing facilities are a major source of risk to upstream and downstream assets. Manual ultrasonic inspection of pipes gives poor reproducibility. Escalating costs are incurred by deploying inspection teams to facilities, obtaining work permits, preparing scaffolding, or in abseiling to access difficult locations.

In response to these challenges, Wi-Corr® UT has been developed to revolutionise the way asset integrity is assessed.

Wi-Corr® UT : Key Points

Certified for explosive atmospheres (IECEx and ATEX Zone 1).

Reduces operational risk with non-intrusive sensors.

Easy, quick, permanent or temporary installation on live plant. No hot work permits necessary.

Earliest detection of metal loss with field- proven industry-leading 0.01mm resolution.

Low profile sensors, can be installed under insulation.

+5 year battery life, live plant replacement.

Automatic reporting and historical trending with easy-to-use software.

Separate wireless and sensing modules provide flexibility in locating transmitter to maximise RF range and minimise repeaters. .

Scalable. Large or small scale deployments.

Wi-Corr® UT Actual Installation - Easy to Install (a Bond System or Clamp System)

Wireless Online CUI Monitoring

(Wi-Corr® CUI)

Wi-Corr® CUI use innovative solutions to manage CUI potential threat

Wi-Corr® CUI is a revolutionary new monitoring system. Through a self-organizing network of permanently installed, wireless-enabled sensors, accurate measurements of moisture content of the thermal insulation over small or large distances can be obtained cost-effectively, so that the conditions that cause Corrosion Under Insulation (CUI) can be precisely monitored.

This information allows concentrations and movements of moisture in insulation to be tracked over great distances, enabling a proactive approach in planning of turnarounds and timely preventative action

The sensor data can remotely detect and predict corrosion development using advanced models and analytics. This can be incorporated into the existing asset management system of the asset owner. Data is used to greatly enhance an existing Risk Based Inspection (RBI) programme, and enabling the move to predictive corrosion management

Wi-Corr® UT : Key Points

Earliest possible detection of potential CUI problems with overall plant dahsboard.

Reduces operational risk with dispersed sensors.

Easy, quick, permanent or temporary installation on live plant. Low profile, wireless sensors, can be installed under insulation. Large or small sensor number deployments.

+5 year battery life, live plant replacement.

Automatic reporting and historical trending with easy-to-use software.

Measurements on demand 24/7.

Separate wireless and sensing modules provide flexibility in locating transmitter to maximise RF range and minimise repeaters.

Scalable. Large or small scale deployments.

Wi-Corr® CUI Actual Installation – Long Range System

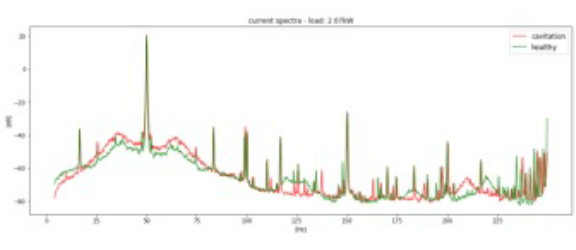

Continuous Online Condition Monitoring using ESA/MCSA

Monitor

Detect

Act

Continuous Online Condition Monitoring for Rotating Equipment

Accurate, intelligent, and powerful machinery analyses and protection based on 30 years of experience.

Global customer support and sales network.

Proven reliable with installations worldwide on all types of critical rotating equipment.

24/7 customer support capability.

Made in Germany.

Online condition monitoring.

SIL 3 machine protection.

Automated diagnostics.

Failure pattern database for clear text messages.

Ring buffer.