Predictive Maintenance

Predictive Risk Assessment for Corrosion and CUI Management System

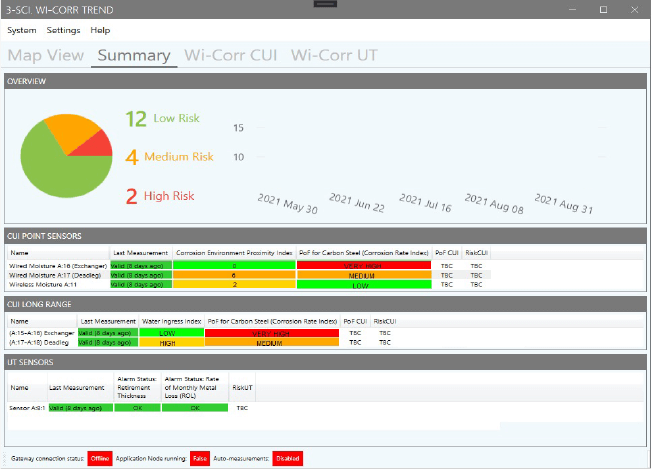

Using proprietary Wi-Corr TREND software, the system provide overall overview on the overall sensors network and location inside the facilities. It provide a quick view through data visualization for asset owner to identify which area or asset that require attention. The classification and prioritization enables a systematic reporting which give early warning and provide opportunity for early intervention.

The system is flexible to accommodate large number of data points and reliable which can support the decision making by the asset owner while keeping the data and incidents tracked over time.

New data, input and parameters are easily scalable based on the improvement that may be required from the asset owner or any industry standard updates or recommendations.

Digital Online Diagnostic for Valve Operability Assessment

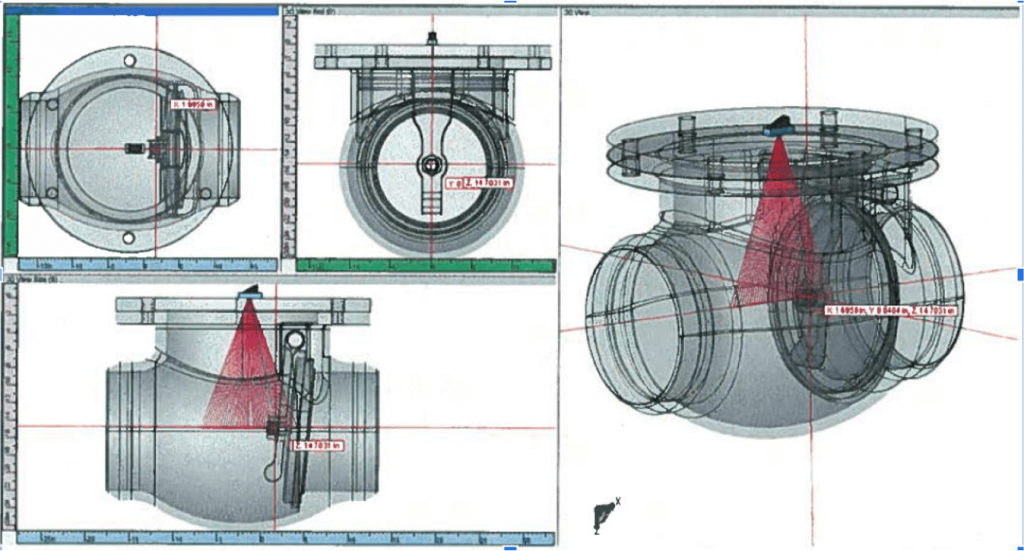

PASS® proprietary technology used advanced method and simulation which allow online diagnostic analysis

Currently, typical methods of non-intrusive tests for valves are acoustic emission, magnetic and radiography. In the acoustic emission method, contact noises from internal components impacting the body or seating areas are detected and analyzed.

However, when the non-intrusive tests are judged to be ineffective due to the valves’ characteristics, disassembly and visual inspections are carried out to verify the valve condition.

Disassembly of valves brings considerable disadvantages in terms of time and cost. Particularly in refinery, petrochemical, LNG plants, disassembly and visual inspection require additional work such as installation of radiation shields, decontamination of the inside of the valves, and strict foreign material control

Using proprietary valve inspection and diagnostic system which is a state-of-the-art nonintrusive valve diagnostic system which adopts the cutting-edge ultrasonic technology to observe the internal components of valves during live/online plant operation. Together with the Visualization Software, it provides a comprehensive solution for Phased Array UT (PAUT) data analysis and field interpretation

Electrical Motor Driven Equipment

Electricity Management

Monitor your electricity consumption at machine level to identify energy waste, and receive saving opportunities.

Predictive Maintenance

Monitor the condition of your machines real-time to prevent machine breakdown, and get notifications.

Water Management

Monitor your water consumption to identify leakage and receive saving opportunities.

Gas Management

Monitor your gas consumption and get personalized saving opportunities to save on your gas bill.

Compressed Air Management

Monitor the flow of your compressed air system, and receive real-time notifications if we identify leakages.

Temperature & Humidity

Monitor your temperature consistently to ensure production quality in your plant

Reciprocating Compressors and Pumps

Protection Analyses

Early Failure Detection

Wear Monitoring

Performance Optimization

Lubrication Monitoring

Monitors the flow rate of every individual lubrication point by trend analysis.

Process Data Analyses

Displays and monitors defined DCS values as trends.