Machine Learning and Artificial Intelligence

(Predictive Maintenance for Rotating Equipment)

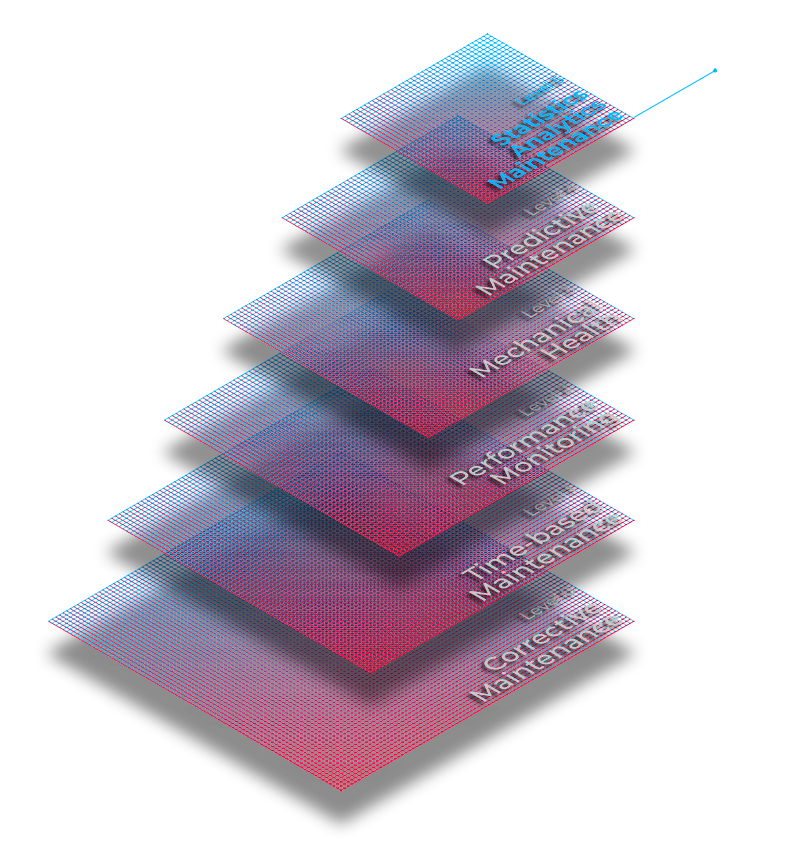

Predictive Maintenance for Rotating Equipment

The integration of our data use and advanced predictive maintenance algorithm allow:

- Our clientele of engineers to forecast possible failures with reliable accuracy

- On ground engineers to avoid exposure to potential hazardous risks upon system assessment

- Our clients to potentially streamline maintenance expenses and shutdown time by predicting the failures of prioritized components

Predictive Maintenance for Rotating Equipment

The integration of our data use and advanced predictive maintenance algorithm allow:

- Our clientele of engineers to forecast possible failures with reliable accuracy

- On ground engineers to avoid exposure to potential hazardous risks upon system assessment

- Our clients to potentially streamline maintenance expenses and shutdown time by predicting the failures of prioritized components