Neuron soundware

Neuron Soundware combines Machine Learning (ML) and Artificial Intelligence (AI) with the analysis of sound and other physical parameters to deliver state-of-the-art solutions for monitoring and controlling machines and manufacturing processes. The company is driven by a belief in challenging the status quo in industrial manufacturing.

Their advanced AI and ML algorithms are designed to maximize equipment and process performance by analyzing a wide range of physical parameters — including sound, temperature, pressure, electric current, magnetic field, luminescence, permeability, and irradiance. These insights provide a comprehensive understanding of the current health, efficiency, and behavior of individual machines and entire production systems.

Integrated Smart Monitoring Solutions

In partnership with Neuron SW, we deliver a fully customisable, end-to-end monitoring ecosystem that integrates hardware, software, and AI analytics into a single, seamless solution.

Our system enables continuous, real-time monitoring of machines, plants, and assets—improving safety, reliability, and operational uptime. From predictive maintenance to automated data acquisition, every solution is engineered to deliver precision, scalability, and performance that meet the most demanding industrial environments.

Reliable, Scalable, and Built for Harsh Environments

Smart Hardware Ecosystem (IoT & Sensors)

Our hardware ecosystem is built around Neuron SW’s Industrial IoT Edge Device technology—an intelligent gateway designed for fast data acquisition, edge analytics, and secure data transmission. With edge computing capability and encrypted communications, the system ensures accuracy and security even in remote or offline operations.

The IoT edge platform integrates seamlessly with a broad range of industrial sensors, including vibration, acoustic, pressure, temperature, and fluid-flow sensors. These durable and sensitive devices capture real-time data for performance diagnostics, environmental safety, and predictive analysis.

Each device is designed for easy installation and compatibility with existing control systems, making it an ideal solution for industrial automation, manufacturing, and energy sectors seeking to optimise uptime and protect equipment integrity.

nGuard Software Platform

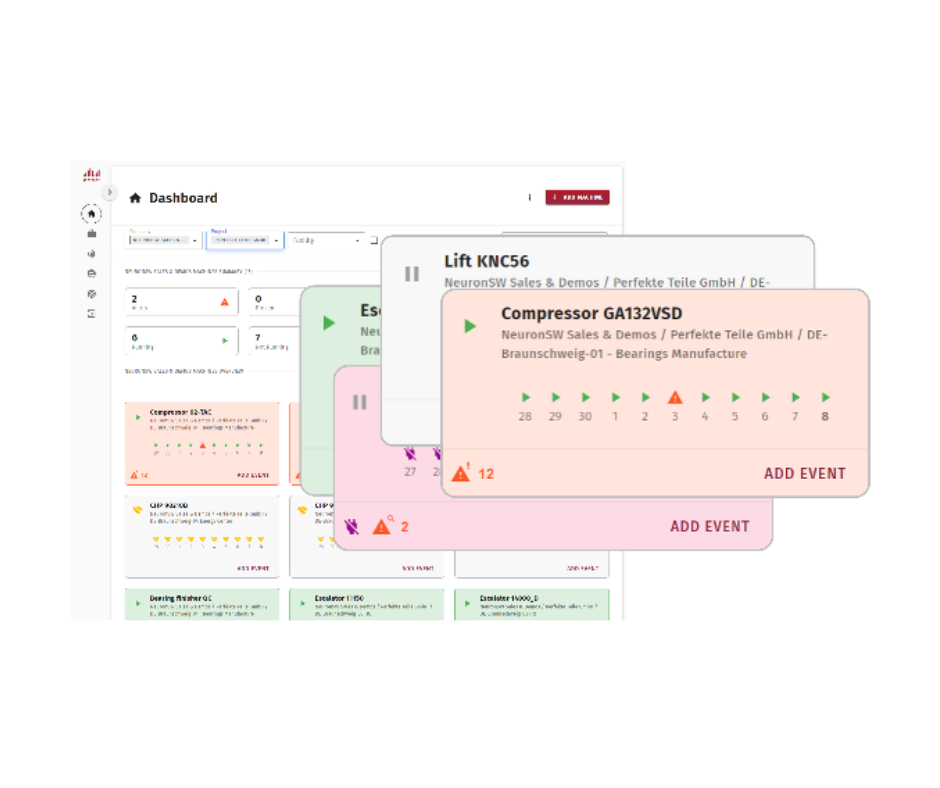

The nGuard web-based platform provides a powerful interface for managing machine health, production status, and operational analytics—all in one dashboard. It transforms complex sensor data into clear, actionable insights for engineers, maintenance teams, and plant managers.

Through machine fleet monitoring, users can track asset conditions, identify anomalies, and detect potential failures before they occur. The state-monitoring function visualises live data streams and historical trends for every connected machine, while the diagnostic engine uses AI algorithms to perform advanced frequency-spectrum and vibration analysis.

Built for accessibility and efficiency, nGuard simplifies site management with transparent configuration of machines, sensors, and alarms—ensuring that decision-makers have the right information at the right time.

Real-Time Insights for Smarter Operations

Precision Data Acquisition for Industrial Intelligence

nEdge Pro – Advanced Edge Computing Device

The nEdge Pro is a next-generation Data Acquisition (DAQ) device designed specifically for high-performance edge computing. It captures and processes data from multiple sensors—including vibration, acoustic, pressure, and temperature—using powerful Nvidia Jetson Orin Nano modules.

Equipped with 8 GB RAM, up to 27 input channels, and 40 TOPs of AI computation, nEdge Pro delivers advanced on-site processing without relying on cloud connectivity. Its modular design supports plug-and-play monitoring, Modbus RTS digital input integration, and scalable storage options up to 1 TB SSD.

Built for reliability and adaptability, nEdge Pro empowers industries to perform real-time analytics, predictive maintenance, and automated diagnostics—reducing downtime while maximising productivity.